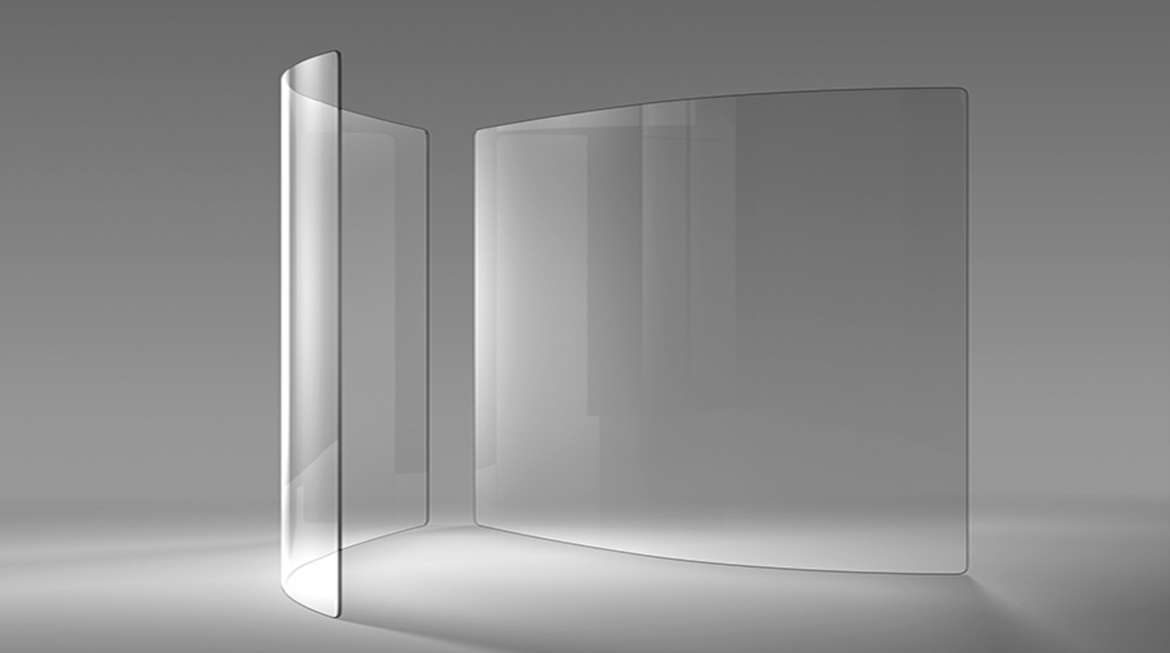

Curved glass, also referred to as bent glass, is glass that has been heated past its softening point and formed into a curved shape, either by annealed gravity bending, or by heat-treated (tempered or heat-strengthened) bending. In case of gravity bending, the softened glass is placed over or into a mould and cooled down slowly after the required shape is achieved.

Although it allows many shapes, gravity bending is time consuming and the coating must withstand a longer heating period. With the heat-treated bending process, the glass is cooled down very quickly immediately after the desired curvature is reached to increase its strength. The main challenges here are how to avoid optical distortions caused by the production process and the limitation to cylindrical shapes and concave shapes when coatings are involved.